| Industrialisering i Höganäs

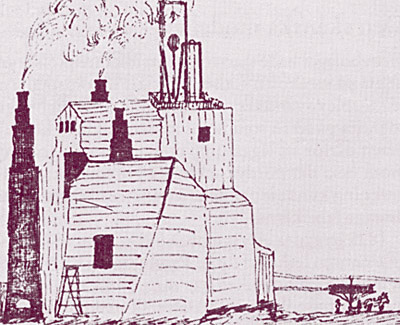

| | Der findes næppe noget som symboliserer industrialiseringen bedre en dampmaskinen. Her ses en tegning af dampmaskinen i Höganäs 1806. (fra Odenkrantz dagbog).

Industrialiseringen af Höganäs er et atypisk eksempel på, hvorledes industrialiseringen i Danmark og Sverige ellers foregik. |

En almindelig opfattelse er, at den svenske industrialisering så småt begyndte efter 1850, og at den først fik fart i slutningen af århundredet. I Sverige sættes den i forbindelse med savværksindustrien i Värmland. Men at den tidlige industrialisering først begyndte i midten af århundredet. Men ingen regel uden undtagelse. En sådan undtagelse er Höganäs, som i 1700-tallet var et lille fiskeleje ved det nordlige Øresund, men som allerede nogle få år inde i 1800-tallet blev forvandlet til en industriegn.

Stenkul

Stenkul associeres normalt med industrialisering, især i England. I Danmark blev stenkulsforekomsterne i Skåne af betydning som energikilde til fyrtårne og kalkbrænderier, og i 1600-tallet brød man stenkul i Helsingborg. Her lå forekomsterne let tilgængelige i jordbunden på skrænterne mod havet nord for byen. I Kullens fyrtårn fyrede man med dette stenkul. Men da Skåne blev svensk, mistede stenkullet sin betydning, da det hverken kunne eller måtte konkurrere med de svenske skove som energikilde.

Kullens fyr |

Stenkul i Skåne |

Stenkul og ler

Den svenske innovatør, Jonas Ahlströmer, som en tid var konsul i London, talte i starten af 1700-tallet for, at stenkulsbrydningen skulle genoptages i Sverige. Eftersom Skåne var det eneste område i Sverige, hvor man havde fundet stenkul, startede han i 1737, Det Skånske Stenkulsværk. Kulforekomster opdagedes bl.a. i Vallåkra udenfor Helsingborg. Foretagendet var ikke særlig lønsomt, og markedet omfattede stadig stort set kun fyrvæsenet.

1786 overtog Erik Ruuth det Skånske Stenkulsværk. Han var greve, administrator, godsejer og blev desuden, i kraft af sin nye virksomhed, tidlig industrimand i Skåne. Han satsede stædigt, og til tider økonomisk dristigt, på det nordvestlige Skånes miner. Anders Polheimer, kendt bjergingeniør, blev ansat for at udføre prøveboringer, og han fandt fine forekomster; bl.a. i egnene omkring det lille fiskeleje, Höganäs, på Kullahalvøen. Dette skete egentlig som resultat af en tilfældighed. Polheimer havde fået øje på gult ler, som bønderne i området solgte som maling. Ved dybdeboringer fandt Polheimer ikke kun ildfast ler, men også stenkul af, efter skånske forhold, udmærket kvalitet.

Eric Ruuth |

Stenkulsminerne |

Engelske ingeniører og de første svenske jernbaner

Formodentlig kom det ikke som nogen overraskelse for en bjergingeniør, at der var stenkul der, hvor der var rigelig med ler. Nu (1797) fremskaffede Ruuth ny kapital, og en rent industriel virksomhed begyndte. Han ansatte en engelsk mineingeniør, som kom fra egnen omkring Newcastle i det nordlige England. Han hed Thomas Stawford, og han så med forundring på sit nye underudviklede hjemland, hvor man ikke havde haft fornuft til at udnytte de fine naturresurser, og hvortil moderne teknik, endnu ikke var nået.

Stawford gennemførte beslutsomt en, på det nærmeste engelsk industrialisering. Den første dampmaskine installeredes allerede i 1798, og flere fulgte i de efterfølgende år. Disse brugtes til at tømme minerne for vand. De skakter, som man havde åbnet i Tjörröd, nord for Höganäs fiskeleje og i Ryd mod øst, havde den store fordel, at de lå forholdsvis tæt ved kysten, og transporterne til udskibningshavne blev derfor korte. 1801-1802 byggedes en kanal fra skakten ned til havet. Denne kanal kunne bruges til flere formål. Dels kunne vandet, som man pumpede op af minerne ved hjælp af Stanfords dampmaskiner, ledes bort, dels kunne kullet fragtes på pramme ned til anløbsstedet for udskibningen. En træskinnebane på næsten 2 km var allerede omkring 1800 blevet etableret mellem forskellige arbejdspladser. 1805 udskiftedes træskinnerne med jernskinner, og således havde Sverige fået sin første jernbane.

Glasværksindustrien og den nye arbejdsdeling

I 1801 gik man i gang med at bygge et glasværk til fremstilling af flasker. Stenkullet var en udmærket energikilde til glashytten (smelteovnen). 1805 produceredes her over 100.000 flasker, som først og fremmest eksporteredes til England og Frankrig.

Arbejdsstyrken i virksomheden var indledningsvis på 15 mand, men voksede hurtigt og i 1806 var 294 arbejdere registrerede i virksomheden. Disse var på daværende tidspunkt fordelt på følgende måde:

Tjenestemænd: 10 stk.

Minearbejdere: 131 stk.

Arbejdere ved maskinerne: 27 stk.

Arbejdere ved glasværket: 11 stk.

Håndværkere: 39 stk.

Transportarbejdere: 12 stk.

Altmuligmænd: 64 stk.

Arbejdet var til dels specialiseret, og f.eks. var minearbejderne inddelte i skaktfogder, sænkere, kulhuggere og kuldrenge. Lignende opdelinger forekom også i forbindelse med maskinarbejde og transportarbejde.

Arbejdskraften hentes andre steder fra

Rekrutteringen af arbejdskraft var under denne periode et problem, og landbrugets rationalisering havde endnu ikke frigjort arbejdskraft i Skåne. Arbejdskraftbehovet var så stort, at den lokale befolkning ikke var tilstrækkelig, og arbejdere blev ansat fra alle mulige kanter. Der kom glasblæsere fra Småland, soldater brugtes til kanalbyggeriet, hallændere, blekingeboere, englændere, tyskere og nordmænd ankom til Höganäs, ja, selv russiske krigsfanger benyttedes 1808-09. Det var ikke helt problemfrit med denne brogede skare. Stawford noterede således ofte i sin dagbog sine bekymringer over arbejdernes fuldskab og slåskampe.

Hårde vilkår

Stawford viste sig hårdhændet overfor arbejderne, men var respekteret af etablissementet for sin driftighed. Arbejdsdagen for en arbejder var normalt 12 timer lang. Klager blev ofte mødt med trussel om arrestation og andre afstraffelser. Kom man ikke i tide, kunne man blive pålagt arbejde i minen uden lys. Arbejdet var hårdt og svært i fugtige, trange mineskakt, og uheld og sygdomme hørte til dagligdagen.

Mange flygtede og børnearbejde forekom i stort omfang. Ifølge en fortegnelse over ”Stenkols Werkets Personal” i december 1827 fandtes der 260 arbejdende mænd og 85 arbejdende drenge, dvs. omtrent 25 % af de ansatte var børn. Men det var såmænd en nedgang sammenlignet med 1802, da cirka 35 % af arbejdsstyrken var børn, men meget tyder på, at det i lang tid var normalt med børnearbejde i Höganäs.

Samtidigt etableredes skoler og hospitaler, og man byggede boliger. Allerede i 1797 påbegyndtes byggeriet af arbejderboliger, som normalt bestod af et værelse med køkken på tilsammen 18 kvadratmeter. I disse lejligheder boede familier på 5-8 personer.

Arbejderbolig 1806 |

Arbejderbolig 1814 |

Bygningskunst og ornamenter

I 1825 omdannedes virksomheden i stenkulsværket. Det var blevet mere lønsomt at bearbejde leret end at udskibe stenkul. Stenkullet brugtes derefter til opvarmning af ovne ved fremstillingen af lervarer, f.eks. tegl og lerkrukker. I 1856 ansattes den danske billedhugger Ferdinand Ring som ornamentbilledhugger ved Höganäsværket og dermed startede den kunstkeramiske produktion.

Den nyklassicistiske stil var nu meget udbredt indenfor bygningskunst, og denne arkitekturstil kendetegnedes især af ornamenter i rigt mål. Ring havde tidligere arbejdet for den verdensberømte danske billedhugger Bertel Thorvaldsen. Han blev i Höganäs til 1869. I byens midt kan man se eksempler på hans kunst, terrakottastatuer af Ruuth og Stenbock men også ornamenter på flere huse. Efter tiden i Höganäs flyttede Ring tilbage til Danmark. Her udførte han nogle berømte udsmykninger, bl.a. frontongruppen på Det Kongelige Teater i København og hans arbejder kan også beses i Marmorkirken.

Dekorerede facader |

Ornamenter |

Höganæs og industrialiseringen som begreb

Man kan diskutere den egentlige betydning af ordet industrialisering, og der findes da også mange opfattelser og teorier, om hvornår den begyndte. Men hvis definitionen er, at industrialisering indebærer overgang til en kapitalistisk ejeform, investeringer i kapitalkrævende maskiner, ansættelse af lønnede arbejdere med vis specialkundskab, stor produktion, nye transportsystemer og en ”stempelurstilværelse”, så var Höganäs industrialiseret tidligt i 1800-tallet, halvtres år før industrialiseringen af savværksindustrien i Midtsverige.

Industrien i Höganäs opstod altså ikke indenfor det lokale landbrugssamfunds rammer og var heller ikke afhængigt af dette samfund, når det gjaldt rekruttering af arbejdskraft eller afsætning af varer. Arbejderne rekrutteredes, som vi har set, fra andre steder, og produkterne, både stenkul og glas, eksporteredes. Höganäs var blevet et lille industri-England med arbejdere, dampmaskiner, stenkul, kanal og jernbane. Og alt dette var i fuld gang allerede i 1805!

Eric Ruuths risikokapital, Anders Polheimers undersøgelser, Thomas Stawfords innovationer og driftighed men først og fremmest hundreder af arbejderes hårde arbejde, havde forandret det lille fiskeleje Höganäs til et industrisamfund. Det første af sin art i Skåne, måske i Sverige. |