| Industrialisering

| | En tidlig industrialisering fandt sted på begge sider af Øresund.

I Höganes blev der ved slutningen af århundredet skabt forudsætninger for en omfattende produktion af flasker. Bl.a. til eksport til England.

I Hellebæk på sjællandssiden blev der igangsat en omfattende fabrikation af forladegeværer til den danske stat. Maleriet er dog fra midten af 1800-tallet. |

Industrialisering i Höganäs

| | Der findes næppe noget som symboliserer industrialiseringen bedre en dampmaskinen. Her ses en tegning af dampmaskinen i Höganäs 1806. (fra Odenkrantz dagbog).

Industrialiseringen af Höganäs er et atypisk eksempel på, hvorledes industrialiseringen i Danmark og Sverige ellers foregik. |

En almindelig opfattelse er, at den svenske industrialisering så småt begyndte efter 1850, og at den først fik fart i slutningen af århundredet. I Sverige sættes den i forbindelse med savværksindustrien i Värmland. Men at den tidlige industrialisering først begyndte i midten af århundredet. Men ingen regel uden undtagelse. En sådan undtagelse er Höganäs, som i 1700-tallet var et lille fiskeleje ved det nordlige Øresund, men som allerede nogle få år inde i 1800-tallet blev forvandlet til en industriegn.

Stenkul

Stenkul associeres normalt med industrialisering, især i England. I Danmark blev stenkulsforekomsterne i Skåne af betydning som energikilde til fyrtårne og kalkbrænderier, og i 1600-tallet brød man stenkul i Helsingborg. Her lå forekomsterne let tilgængelige i jordbunden på skrænterne mod havet nord for byen. I Kullens fyrtårn fyrede man med dette stenkul. Men da Skåne blev svensk, mistede stenkullet sin betydning, da det hverken kunne eller måtte konkurrere med de svenske skove som energikilde.

Kullens fyr |

Stenkul i Skåne |

Stenkul og ler

Den svenske innovatør, Jonas Ahlströmer, som en tid var konsul i London, talte i starten af 1700-tallet for, at stenkulsbrydningen skulle genoptages i Sverige. Eftersom Skåne var det eneste område i Sverige, hvor man havde fundet stenkul, startede han i 1737, Det Skånske Stenkulsværk. Kulforekomster opdagedes bl.a. i Vallåkra udenfor Helsingborg. Foretagendet var ikke særlig lønsomt, og markedet omfattede stadig stort set kun fyrvæsenet.

1786 overtog Erik Ruuth det Skånske Stenkulsværk. Han var greve, administrator, godsejer og blev desuden, i kraft af sin nye virksomhed, tidlig industrimand i Skåne. Han satsede stædigt, og til tider økonomisk dristigt, på det nordvestlige Skånes miner. Anders Polheimer, kendt bjergingeniør, blev ansat for at udføre prøveboringer, og han fandt fine forekomster; bl.a. i egnene omkring det lille fiskeleje, Höganäs, på Kullahalvøen. Dette skete egentlig som resultat af en tilfældighed. Polheimer havde fået øje på gult ler, som bønderne i området solgte som maling. Ved dybdeboringer fandt Polheimer ikke kun ildfast ler, men også stenkul af, efter skånske forhold, udmærket kvalitet.

Eric Ruuth |

Stenkulsminerne |

Engelske ingeniører og de første svenske jernbaner

Formodentlig kom det ikke som nogen overraskelse for en bjergingeniør, at der var stenkul der, hvor der var rigelig med ler. Nu (1797) fremskaffede Ruuth ny kapital, og en rent industriel virksomhed begyndte. Han ansatte en engelsk mineingeniør, som kom fra egnen omkring Newcastle i det nordlige England. Han hed Thomas Stawford, og han så med forundring på sit nye underudviklede hjemland, hvor man ikke havde haft fornuft til at udnytte de fine naturresurser, og hvortil moderne teknik, endnu ikke var nået.

Stawford gennemførte beslutsomt en, på det nærmeste engelsk industrialisering. Den første dampmaskine installeredes allerede i 1798, og flere fulgte i de efterfølgende år. Disse brugtes til at tømme minerne for vand. De skakter, som man havde åbnet i Tjörröd, nord for Höganäs fiskeleje og i Ryd mod øst, havde den store fordel, at de lå forholdsvis tæt ved kysten, og transporterne til udskibningshavne blev derfor korte. 1801-1802 byggedes en kanal fra skakten ned til havet. Denne kanal kunne bruges til flere formål. Dels kunne vandet, som man pumpede op af minerne ved hjælp af Stanfords dampmaskiner, ledes bort, dels kunne kullet fragtes på pramme ned til anløbsstedet for udskibningen. En træskinnebane på næsten 2 km var allerede omkring 1800 blevet etableret mellem forskellige arbejdspladser. 1805 udskiftedes træskinnerne med jernskinner, og således havde Sverige fået sin første jernbane.

Glasværksindustrien og den nye arbejdsdeling

I 1801 gik man i gang med at bygge et glasværk til fremstilling af flasker. Stenkullet var en udmærket energikilde til glashytten (smelteovnen). 1805 produceredes her over 100.000 flasker, som først og fremmest eksporteredes til England og Frankrig.

Arbejdsstyrken i virksomheden var indledningsvis på 15 mand, men voksede hurtigt og i 1806 var 294 arbejdere registrerede i virksomheden. Disse var på daværende tidspunkt fordelt på følgende måde:

Tjenestemænd: 10 stk.

Minearbejdere: 131 stk.

Arbejdere ved maskinerne: 27 stk.

Arbejdere ved glasværket: 11 stk.

Håndværkere: 39 stk.

Transportarbejdere: 12 stk.

Altmuligmænd: 64 stk.

Arbejdet var til dels specialiseret, og f.eks. var minearbejderne inddelte i skaktfogder, sænkere, kulhuggere og kuldrenge. Lignende opdelinger forekom også i forbindelse med maskinarbejde og transportarbejde.

Arbejdskraften hentes andre steder fra

Rekrutteringen af arbejdskraft var under denne periode et problem, og landbrugets rationalisering havde endnu ikke frigjort arbejdskraft i Skåne. Arbejdskraftbehovet var så stort, at den lokale befolkning ikke var tilstrækkelig, og arbejdere blev ansat fra alle mulige kanter. Der kom glasblæsere fra Småland, soldater brugtes til kanalbyggeriet, hallændere, blekingeboere, englændere, tyskere og nordmænd ankom til Höganäs, ja, selv russiske krigsfanger benyttedes 1808-09. Det var ikke helt problemfrit med denne brogede skare. Stawford noterede således ofte i sin dagbog sine bekymringer over arbejdernes fuldskab og slåskampe.

Hårde vilkår

Stawford viste sig hårdhændet overfor arbejderne, men var respekteret af etablissementet for sin driftighed. Arbejdsdagen for en arbejder var normalt 12 timer lang. Klager blev ofte mødt med trussel om arrestation og andre afstraffelser. Kom man ikke i tide, kunne man blive pålagt arbejde i minen uden lys. Arbejdet var hårdt og svært i fugtige, trange mineskakt, og uheld og sygdomme hørte til dagligdagen.

Mange flygtede og børnearbejde forekom i stort omfang. Ifølge en fortegnelse over ”Stenkols Werkets Personal” i december 1827 fandtes der 260 arbejdende mænd og 85 arbejdende drenge, dvs. omtrent 25 % af de ansatte var børn. Men det var såmænd en nedgang sammenlignet med 1802, da cirka 35 % af arbejdsstyrken var børn, men meget tyder på, at det i lang tid var normalt med børnearbejde i Höganäs.

Samtidigt etableredes skoler og hospitaler, og man byggede boliger. Allerede i 1797 påbegyndtes byggeriet af arbejderboliger, som normalt bestod af et værelse med køkken på tilsammen 18 kvadratmeter. I disse lejligheder boede familier på 5-8 personer.

Arbejderbolig 1806 |

Arbejderbolig 1814 |

Bygningskunst og ornamenter

I 1825 omdannedes virksomheden i stenkulsværket. Det var blevet mere lønsomt at bearbejde leret end at udskibe stenkul. Stenkullet brugtes derefter til opvarmning af ovne ved fremstillingen af lervarer, f.eks. tegl og lerkrukker. I 1856 ansattes den danske billedhugger Ferdinand Ring som ornamentbilledhugger ved Höganäsværket og dermed startede den kunstkeramiske produktion.

Den nyklassicistiske stil var nu meget udbredt indenfor bygningskunst, og denne arkitekturstil kendetegnedes især af ornamenter i rigt mål. Ring havde tidligere arbejdet for den verdensberømte danske billedhugger Bertel Thorvaldsen. Han blev i Höganäs til 1869. I byens midt kan man se eksempler på hans kunst, terrakottastatuer af Ruuth og Stenbock men også ornamenter på flere huse. Efter tiden i Höganäs flyttede Ring tilbage til Danmark. Her udførte han nogle berømte udsmykninger, bl.a. frontongruppen på Det Kongelige Teater i København og hans arbejder kan også beses i Marmorkirken.

Dekorerede facader |

Ornamenter |

Höganæs og industrialiseringen som begreb

Man kan diskutere den egentlige betydning af ordet industrialisering, og der findes da også mange opfattelser og teorier, om hvornår den begyndte. Men hvis definitionen er, at industrialisering indebærer overgang til en kapitalistisk ejeform, investeringer i kapitalkrævende maskiner, ansættelse af lønnede arbejdere med vis specialkundskab, stor produktion, nye transportsystemer og en ”stempelurstilværelse”, så var Höganäs industrialiseret tidligt i 1800-tallet, halvtres år før industrialiseringen af savværksindustrien i Midtsverige.

Industrien i Höganäs opstod altså ikke indenfor det lokale landbrugssamfunds rammer og var heller ikke afhængigt af dette samfund, når det gjaldt rekruttering af arbejdskraft eller afsætning af varer. Arbejderne rekrutteredes, som vi har set, fra andre steder, og produkterne, både stenkul og glas, eksporteredes. Höganäs var blevet et lille industri-England med arbejdere, dampmaskiner, stenkul, kanal og jernbane. Og alt dette var i fuld gang allerede i 1805!

Eric Ruuths risikokapital, Anders Polheimers undersøgelser, Thomas Stawfords innovationer og driftighed men først og fremmest hundreder af arbejderes hårde arbejde, havde forandret det lille fiskeleje Höganäs til et industrisamfund. Det første af sin art i Skåne, måske i Sverige.Industrialisering i Hellebæk

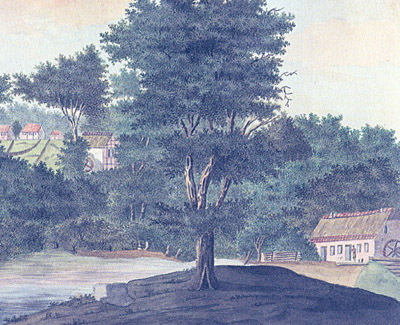

| | I 1700-tallet tager den begyndende industrialisering fart flere steder på Sjælland bl.a. i Hellebæk på Nordkysten seks kilometer fra Helsingør. Udgangspunktet var udnyttelsen af den vandkraft der var til stede her. I Hellebæk drejede det sig om fabrikation af våben, primært geværer til den danske hær. Hammermøllen, som ses midt i billedet, var den centrale del af forarbejdningsanlægget. |

Vandkraftens betydning

Ved påbegyndelsen af byggeriet på Kronborg i Frederik 2.s tid blev man opmærksom på mulighederne for at udnytte den vandkraft, der var til stede i omegnen, først og fremmest i Hellebæk. Med henblik på at forsyne de mange arbejdere med brød byggede man i første omgang en kornmølle helt nede ved stranden, men under Christian 4. begyndte man også at interessere sig for andre projekter. Da man omkring århundredeskiftet fandt myremalm i området iværksatte han et projekt, der tog sigte på at udsmelte og bearbejde jernmalm herfra. I 1601 beskikkes således en Poul Smelter til:

”...i den nye Smeltemølle, som vi ved vort Slot Kronborg haver ladet bygge, med Flid og uden Forsømmelse at skulle smelte og bearbejde den Jernerts, som sammesteds udi Lenet findes".

Forsøg med jernfremstilling

Projektet med jernfremstilling bliver aldrig nogen succes, det forlægges i stedet til Norge, men man fortsætter med at smede forskellige jernemner i et anseligt omfang, over 10.000 stykker smedegods til Frederiksborg Slot, bl.a. under ledelse af Caspar Fincke, der var mestersvend ved møllen i perioden 1622-1630. Der var tale om allehånde forskellige produkter, såsom låse, hængsler, dørklinker og viduesgitre. Der blev også opført en kobbermølle i området, antagelig med vand fra Kobberdammen som drivkraft, men omstændighederne er her mere uklare. Kobberplader skulle bl.a. anvendes til tag på kongens mange bygninger. Det samlede anlæg fungerede frem til omkring 1650, men ødelægges af svenskerne under krigen i 1658. Herefter går der omkring 100 år før der for alvor kommer gang i tingene igen.

Udnyttelse af vandkraften

Forudsætningen for hele foretagendet var udnyttelsen af vandressourcerne i området og det omfattende reguleringssystem, der skulle sikre stabil vandtilførsel hele året rundt.

Det centrale område for udnyttelsen af vandkraften er Hellebækken, der løber fra Bondedammen til stranden nedenfor med et fald på over 20 meter. Arbejdet med at opdæmme og udnytte vandkraftsystemet påbegyndes i 1575 med arbejdskraft fra Helsingør. I første omgang tager man fat på den nedre del af systemet, men allerede i 1577 graves der en kanal imellem Sortesø og Klaresø. Der har ligget et stort arbejde i den løbende vedligeholdelse af både vandsystemet og møllerne.

Hammermøllen |

Vandsystemet ved Hellebæk |

Geværfabrikken i Hellebæk

I starten af 1700-tallet er der planer om at anlægge en geværfabrik i Hellebæk, men først da værket sættes på auktion i 1743 og regimentskvartermester Stephan Hansen fra Helsingør overtager det for 15.250 rigsdaler bliver det for alvor til noget.

Stephan Hansen er et godt eksempel fra denne tid på en borgerlig, egentlig bondesøn, der med flid og arbejdsomhed tjener sig op i samfundet. I forbindelse med anlæggelse af geværfabrikken oplever vi ham som privat iværksætter, idet han ganske vist får monopol på at fremstille geværer i 20 år. I 1743 var han ved at gøre karriere indenfor militæret og fungerede også som købmand i Helsingør. I perioden fra 1750-1770 havde han desuden handelsret på Færøerne. Omkring 1750 lader han Hellebækgård opføre i sammenhæng med sine udvidelser af foretagendet.

Stephan Hansen formår at reorganisere og forny hele værket. Gamle bygninger istandsættes, han indkalder fagfolk fra udlandet og opfører en række nye bygninger, heriblandt de karakteristiske gule mesterboliger i Bøssemagergade, hvor en række håndværksmestre og deres svende boede og arbejdede.

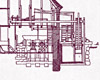

Samtidigt kort over anlægget

I 1752 tegnede en ansat ved værket et kort over anlægget. Kortet viser strækningen fra Bondedammen og ned til kysten. Ifølge kortet er der på dette tidspunkt 2 hammermøller. Det menes, at den ene har haft et såkaldt overfaldshjul, den anden som det nu kan ses på den restaurerede mølle et underfaldshjul. Den oprindelige mølle ombygges i Stephan Hansens tid og står færdig 1765, samme år som staten køber værket tilbage.

I forbindelse med restaureringen af møllen omkring 1980 har man rekonstrueret den udvidede mølle fra 1765. Møllehjulene var placeret ved gavlenden. Det højeste hjul, 6 meter i diameter og 3/4 meter bredt, driver blæsebælgen til essen indenfor, mens det lavere hjul, 5 meter i diameter og 1,5 meter bredt, driver to hamre, en såkaldt strækhammer, hvis hoved vejer 100 kilo, og en løbhammer, der vejer 20 kilo. der er endvidere forbindelse til blæsebælgene på loftet.

Kort over anlægget 1752 |

Hammermøllen |

Tværsnit over mølleværket |

Den ny hammermølle |

Overgangen fra håndværk til industri

Interessant ved værket i Hellebæk er dets karakter af overgangsform fra rent håndværksmæssig produktion til den senere tids egentlige industri.

Karakteristisk for håndværket er, ideelt set, at få faglærte arbejdere individuelt udformer produkterne med enkle redskaber og i reglen til et kendt marked, som f.eks. Helsingør med opland.

I modsætning hertil er den industrielle produktion rettet imod et ukendt, eller foranderligt marked, og produktionen er opdelt i delprocesser og finder sted ved hjælp af et antal maskiner, der drives ved mekanisk kraft.Som overgangsformer opererer man endvidere med to hovedformer: Manufakturvirksomhed og forlagsindustri.

Manufakturvirksomhed

Manufakturen er karakteriseret ved at man samler et stort antal arbejdere på et og samme sted (bygning). Der er tale om en begyndende arbejdsdeling, men endnu ikke en fælles kraftkilde, der dikterer arbejdsgangen.

Denne produktionsform findes i Danmark allerede på 331V.s tid i form af statsmanufakturer, der skulle forsyne hoffet med f.eks. silkeprodukter. I denne form er der tale om en national selvforsyningsstrategi, og altså et ”lukket" marked, der skulle medvirke til at sikre uafhængighed på strategiske områder. Leverancer til hæren af krudt, kugler m.m. er også karakteristisk, og det her statens interesse for geværfabrikken i Hellebæk kommer ind.

Forlagsindustri

Forlagsindustrien fokuserer primært på produktionens tilrettelæggelse i henseende til finansiering og afsætning af varerne. Selve produktionen er forlagt til arbejdernes hjem, typisk i forbindelse med tidlig tekstilproduktion. Forlæggeren leverer råstoffer til produktion, ofte tillige arbejdsredskaberne og sørger for at aftage og afsætte varerne. Denne produktionsform er karakteristisk for tidlig tekstilproduktion i Danmark og findes endnu i form af hjemmesyerskers arbejde.

Det kan herefter være interessant at forsøge at bestemme, hvilken type af virksomhed geværfabrikken udgør. Som hjælp hertil kan man endvidere inddrage en beskrivelse af selve produktionsgangen:

"For at følge Hellebæks udvikling kan det være nyttigt at se, hvorledes der blev fremstillet geværer, og hvorledes udviklingen i geværernes konstruktion skred frem. Fabrikationen omfattede geværer, ladestokke og bajonetter. Og de enkelte dele blev fremstillet i adskilte møller og værksteder.

I Hammermøllen blev geværløbene smedet. Jernet blev smedet ud til en strimmel, der var lidt længere, end løbet skulle være. Strimmelen blev på en ambolt med et hak bøjet til U-form. Jernet blev derefter bukket om en dorn. Efter at emnet var opvarmet til svejsevarme, blev det svejset sammen uden om en dorn under en vandhammer med sænkere med cylindriske fordybninger i både ambolt og hammer. Når der så blev svejset en bundprop i den ene ende, var løbet klar til udboring og slibning. Disse operationer foregik i særlige møller.

En dygtig smed kunne smede 2 1/2 løb på en arbejdsdag, antagelig 12 timer. Ladestokke og bajonetter blev smedet i en særlig hammermølle; de havde også egne slibemøller. Låsene og andet tilbehør blev smedet af smede, der havde værksteder i forbindelse med deres boliger. Der var også værksteder for skæfterne, der blev lavet af valnøddetræ, eller for de mindre fine geværers vedkommende af elmetræ.

Når løbet var færdigt, blev det prøvet af værkets probermester i "Proberhuset", der stadig findes i Hellebæk. Bygningen er delt i to dele. Den ene er muret og forsynet med tegltag. Den var værksted for probermesteren... Under afprøvningen blev løbene fastspændt med indtil 50 stykker ad gangen. Der var så en rende til fængkrudt, som kunne antændes udefra..."

"Af de prøvede geværer sprængtes ca. 4,5% ved prøven af en samlet produktion på 88.700 løb, og af de færdige geværer kasseredes 18,2%. Til rest blev ca. 70.000 stk. (perioden 1800-1819) Det var derfor ikke mærkeligt, at geværskytterne i gamle dage bad en bøn, før de affyrede et skud, og hurtigskydning kunne det ikke blive til.

Nogle af de geværer, der kasseredes i København, blev dog anvendt; de blev brugt som betaling for varer i de oversøiske lande, f.eks. for slaver. Mange af disse geværer sprængtes ret hurtigt, men det anfægtede ikke sælgerne."

Det kan tilføjes Kislings beskrivelse, at mestersvenden som regel kunne vælge imellem at modtage råvarer (jern og kul) afmålt, eller få arbejdet i entreprise og så selv skulle bekoste indkøb af råvarer. Endvidere antages, at de ansatte bøssemagere har kunnet udføre samtlige processer i fremstillingen, men at der i praksis har været tale om specialisering i enkelte delprocesser.

Staten blander sig

I 1765 køber staten det samlede værk i Hellebæk tilbage fra Stephan Hansen for den nette sum af 120.000 rigsdaler. I 1767 er kongen ved at overdrage værket til generalmajor J. F. Classen, der i forvejen har skøde på krudtværket i Frederiksværk, mod at der årligt leveres 6.000 geværer.

Imidlertid lægger finansministeren H. C. Schimmelmann sig imellem og foranlediger, at værket sættes på auktion, hvor han byder 1.000 rigsdaler over Stephan Hansens søn og erhverver foretagendet for 70.000 rigsdaler.

Hellebækgård |

Industribaronen

H.C. Schimmelmann var ligesom Stephan Hansen opkomling, søn af en pommersk købmand, og allerede hovedrig, da han i 1761 knyttes til den danske regering som finansiel rådgiver og garant. Han får formidlet store lån til den danske stat og sanerer statsfinanserne. Der sker bl.a. gennem salg af statens aktiver, frasalg af krongods, men også diverse statsvirksomheder.

Selv opkøber Schimmelmann godset Lindenborg og bliver adlet (baroniseret). Nok så interessant i denne sammenhæng er hans køb af statens sukkerplantager i Vestindien med tilhørende raffinaderier for 400.000 rigsdaler.

Schimmelmann (1724-1782) |

H.C. Schimmelmann (1724-1782) |

Fregatten Fredensborg |

Trekantshandelen

Med købet af geværfabrikken i Hellebæk er Schimmelmann egenhændigt i stand til at indtræde i den for tiden så karakteristiske trekantshandel imellem Europa, Afrika og Amerika. Færdigvarer, såsom geværer afskibes fra Europa til Afrika, hvor varerne byttes med slaver, der sendes til Vestindien. Herfra hentes råvarer bl.a. sukker, som så sendes til videre forarbejdning i Danmark. Hertil kom at Schimmelmann også havde monopol på sukkersalg til Norge.

Schimmelmann havde altså også andel i slavehandelen og et af slavetransportskibene bar navnet "Grevinde Schimmelmann". H.C. Schimmelmanns søn Ernst arbejdede senere aktivt for at ophæve negerhandelen. I 1792 indføres der med en overgangsperiode på 10 år forbud imod at indføre slaver til Vestindien, men de kunne stadigvæk handles på øerne, og ægtefæller og børn og forældre kunne fortsat adskilles ved salg.

Forladergeværet – en forældet konstruktion

I Stephan Hansens tid fremstilledes årligt omkring 3000 geværer, i perioden 1769-1800 ca. 6000 stk. årligt. Geværproduktionen fortsætter op igennem 1800-tallet, men under krigen i 1864 viser de langsommelige forladegeværer sig at være teknologisk forældede og produktionen opgives. Hvor møjsommeligt affyringsprocessen var giver et uddrag af "Bestemmelser for geværets ladning" fra 1863 et indtryk af. |